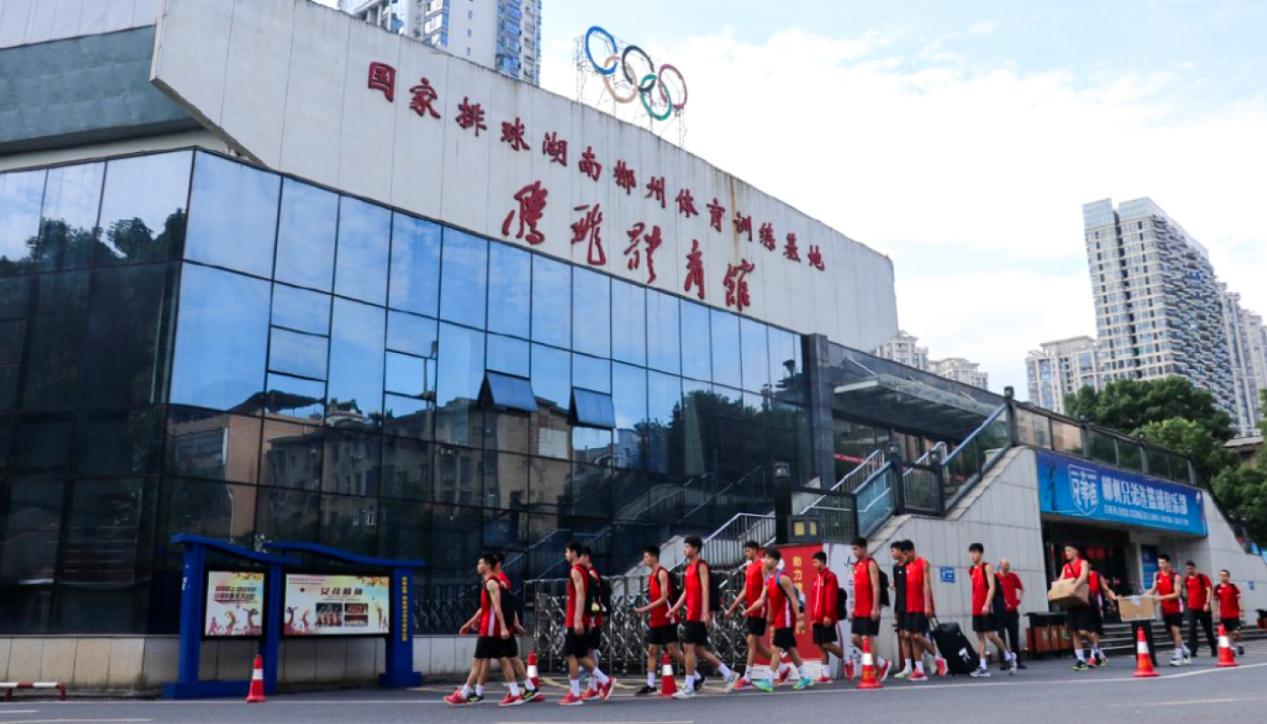

Recently, reporters learned from a national volleyball team training base in Hunan that the “intelligent heavy-duty volleyball machine,” exclusively developed by SIBOASI, has officially entered service with the national team. It is understood that the SIBOASI heavy-duty volleyball machine easily broke the world record of 138 km/h, held for nine years by American men’s volleyball star Stanley, and increased the speed to 158 km/h, setting a new limit in volleyball. A coach at the training base stated that the heavy-duty volleyball machine has achieved world-leading levels in volleyball serving speed, accuracy, and technical and tactical skills. This is playing an irreplaceable role in training the national team’s high-level volleyball players in high-level physical confrontation, adaptability, and coordination.

Breaking a 9-year-old world record, creating a new industry limit of 158 km/h.

The SIBOASI heavy-duty volleyball machine, with its three-axis serving wheel, 360-degree rotating serving technology, and laser positioning, fills a technological gap in the world sports industry for “powerful, high-speed, precise ball feeding, and full-scenario coverage in volleyball training.” This equipment has officially become a core weapon for the national volleyball team in their preparation for various competitions.

At a training base of the national volleyball team in Hunan, a SIBOASI staff member stated, “This is not simply an increase in speed, but a breakthrough in the industry’s speed saturation bottleneck.” Currently, the top European and American serving machines have a maximum speed of 120 km/h, while the world record for men’s volleyball spike speed is 138 km/h, set by American player Stanley. Traditional serving machines have a “speed ceiling” due to the limited contact time between the friction wheel and the ball – when the flywheel speed exceeds a critical value, the ball cannot accelerate further due to sliding friction. This equipment adopts a three-axis co-directional bundling technology, increasing the volleyball acceleration distance by five times. By extending the duration of external force, it breaks through the kinetic energy limit, allowing the final ball speed to reach the linear speed of the friction wheel edge, achieving a linear increase in power.

A serving speed of 158 km/h is equivalent to allowing athletes to face “ultra-extreme” competition that is 14% faster than that of top players during training. “According to preliminary calculations, after three months of training with this equipment, the team’s main attackers can reduce their reaction time to balls traveling at speeds exceeding 120 km/h from 0.38 seconds to 0.29 seconds, and their successful defensive ball retrieval rate increases by 27%. This aligns perfectly with the theory of “optimizing kinetic chain transmission efficiency through extreme load training” in the research paper “Integrated Methods for Strength and Speed Training of Volleyball Players.”

Manual Serve Control: Replicating Realistic Match Scenarios

The manual serve control design of the SIBOASI heavy-duty volleyball machine allows coaches to adjust the timing and trajectory of serves at any time. This “human-machine collaboration” model breaks the limitations of preset programs, making the serving rhythm closer to the unpredictable confrontations in real matches. Players at the training site commented that traditional machines have too regular a serving rhythm, easily leading to blind spots in muscle memory. However, this equipment can simulate the “ups and downs” of serving combinations in a match, significantly enhancing our emergency defensive capabilities. Experimental data shows that athletes using manual serve training improved their visual-motor response speed by an average of 0.12 seconds.

Three-Axis Coaxial Technology: The Only System in the Industry to Achieve 360° Spin and Precise Ball Placement

The three-axis servo serving wheel of the SIBOASI heavy-duty volleyball machine sets a new technical benchmark. By precisely setting the travel parameters of the three serving wheels via a touchscreen, independent motors accurately control the speed difference of the three serving wheels, allowing it to accurately deliver left-spin, right-spin, side-spin, and other full-angle spinning balls. Combined with the Magnus effect of fluid dynamics, topspin balls can achieve “rapid descent” (the drop angle is increased by 45° compared to traditional equipment), while backspin balls “drift and land far away,” perfectly simulating Boskovic’s powerful jump serve and Egonu’s side-spin serving tactics.

The triangular positioning principle of the SIBOASI heavy-duty volleyball machine, combined with a laser positioning system, achieves a landing point accuracy of ±2 cm through dynamic positioning algorithms, complying with the GB/T 22752-2008 sports equipment safety standard and covering the entire court area from position 1 to position 6. Previously, training required three assistant coaches to feed the balls; now, one device can complete specialized training such as “fixed-point blocking” and “area defense.” For example, the SIBOASI heavy-duty volleyball machine’s targeted training for back-row defense against powerful attacks from the fourth position yielded immediate results.

National team coaches provided hands-on guidance, perfectly combining theory and practice.

“From the laboratory to the final product, we went through more than 12 rounds of specialized adjustments,” a SIBOASI staff member revealed. “The entire product development process was guided by the national volleyball coaching team, optimizing 23 parameters such as serving arc and spin intensity in real-world scenarios. According to the trial report at the training base, the SIBOASI heavy-duty volleyball machine is undergoing high-intensity testing, with serving stability reaching 99.2%. We are confident that it will become a core piece of equipment for preparing for international competitions.”

It is understood that the SIBOASI heavy-duty volleyball machine is not the first instance of SIBOASI’s in-depth collaboration with the sports world in intelligent volleyball equipment. As a leading enterprise that has been deeply involved in intelligent serving equipment for 20 years, its first-generation intelligent volleyball serving machine product appeared in the movie “Leap.” This 2.0 version, building on the 1.0 version, features a more groundbreaking 100-level force adjustment system—level 1 speed is 30 kilometers per hour, suitable for 8-12 year old youth training players (meeting the safety standards for sports equipment in primary and secondary schools GB/T 22752-2008); level 50 speed is 85 kilometers per hour, suitable for U16 youth teams; and level 100 reaches 158 kilometers per hour, meeting Olympic-level training needs. “This stepped load design is of great significance. The same equipment can meet the training needs of all stages, from beginner to professional, and saves the cost of frequently changing equipment.”

SIBOASI’s heavy-duty volleyball machine has not only rewritten the technical standards for volleyball training equipment in China and the world, but has also boosted China’s influence in the field of intelligent sports. As a leading intelligent sports company founded in 2006, from the release of its first-generation intelligent tennis equipment in 2006 to becoming a designated supplier for the Chinese Badminton Association and Tennis Association in 2019, the company has consistently focused on the development of the intelligent sports industry as its core strategy. In 2020, it was recognized as a National High-Tech Enterprise. Now, the SIBOASI R&D team is focusing on the development trends of volleyball, overcoming two major challenges: “balancing high speed and precision” and “adapting to multiple scenarios.” As SIBOASI founder and Chairman Wan Houquan stated: “After 20 years of dedicated hard work, SIBOASI has transformed from an industry follower in the research and manufacturing of high-end sports equipment to a global rule-maker and top-tier explorer. Our goal is not only to serve the national team, but also to allow every volleyball enthusiast to access cutting-edge training technology.”

Post time: Dec-30-2025